In this article, we discuss how to produce paper sustainably and the actions companies can take to reduce the environmental impact of the production cycle.

Paper can be produced sustainably by:

- Reducing Water Consumption in Production

- Reducing water consumption in paper production is among the 17 goals of the Global Agenda for Sustainable Development to be achieved by 2030.

- Implementing a closed-loop water system is a strategy to recover and reuse water, with approximately 50% of water being recycled and reintegrated into the production cycle.

- Other strategies include using water recovery systems with proper filtration for reuse, monitoring water usage per production cycle, purification processes to reuse water, advanced technologies to reduce water volume, and automated processes for cleaning and maintaining production machinery.

- Natural Gas with Lower CO2 Emissions

- Using natural gas with lower CO2 emissions is an effective solution for sustainable paper production.

- Natural gas is less polluting than other fossil fuels, ensuring lower CO2 emissions.

- Companies can adopt cogeneration plants to produce electricity and heat efficiently from natural gas, reducing energy consumption and fossil fuel usage.

- Trigeneration plants powered by natural gas can also self-generate electricity from renewable sources through photovoltaic systems.

- Trigeneration plants use high-efficiency internal combustion engines with natural gas, minimizing particulate emissions compared to diesel engines.

- Energy Efficiency

- Energy efficiency interventions optimize energy consumption and production efficiency while minimizing environmental impact.

- Retrofitting traditional lighting systems with LED lighting (relamping) reduces energy consumption by about 70% compared to traditional systems, lowers CO2 emissions, requires minimal maintenance costs, and provides control capabilities.

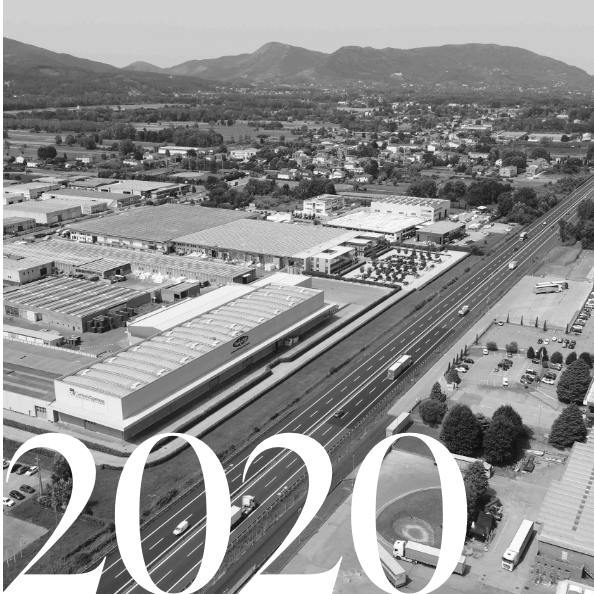

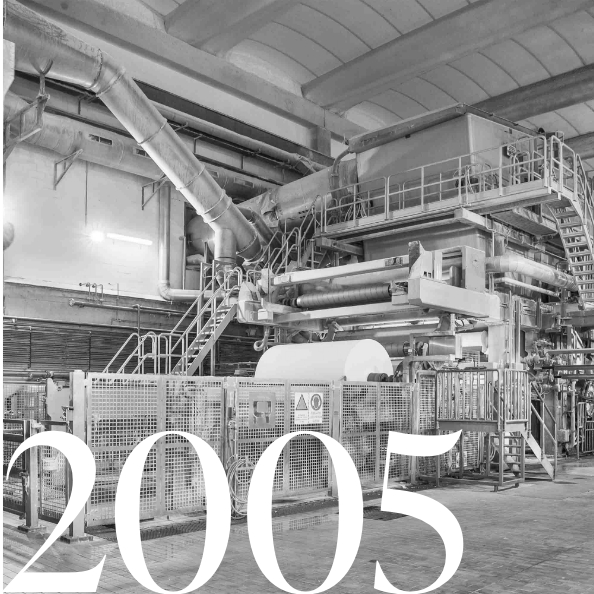

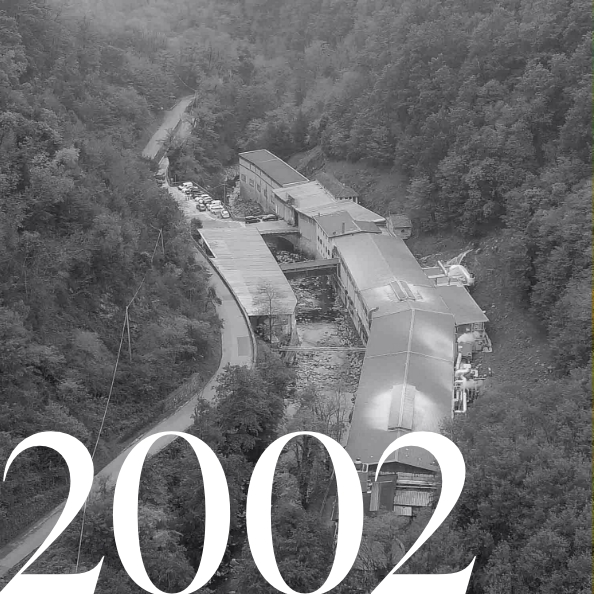

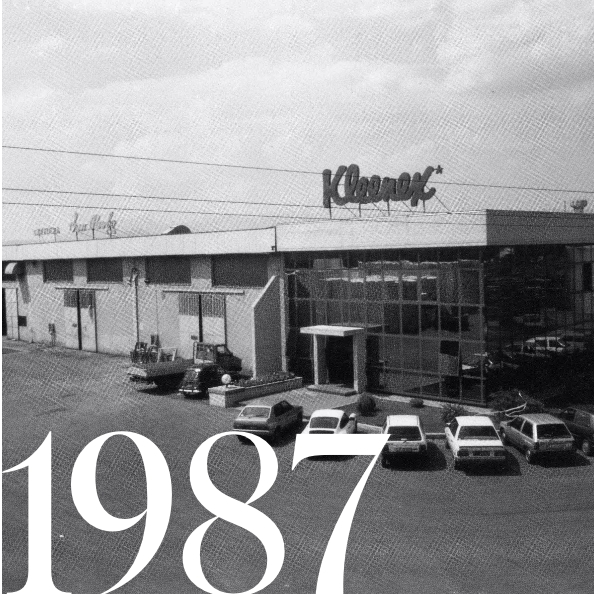

Cartiere Carrara is one of the leading companies in Italy and Europe in the integrated production of high-quality tissue paper. In Cartiere Carrara’s mission and vision, there is a commitment to contributing to a sustainable future by offering high-quality tissue products with the latest technological innovations while respecting the environment and the community.

The company’s environmental commitment surpasses industry standards, focusing on renewable raw materials, efficient resource use, CO2 emissions reduction, and water recycling. Cartiere Carrara adheres to various voluntary certification systems for continuous improvement:

- UNI EN ISO 9001:2015 for quality

- UNI EN ISO 14001:2015 for environmental management

- UNI EN ISO 45001:2018 for health and safety

- PEFC-FSC for product certification in the forest chain of custody

- ECOLABEL Regulation

- UNI EN ISO 50001 – Energy Management System

Cartiere Carrara’s certifications ensure the company operates in compliance with international standards, aiming for continuous improvement and sustainability