Our Vice President and & Chief Growth Officer, Mario Carrara, shared with the industry magazine Industria della Carta, which dedicated a special feature to water treatment, how Cartiere Carrara is investing in advanced technologies to optimize water consumption and reduce environmental impact.

In 2023, we reduced water withdrawal by 9%, thanks to innovative wastewater treatment and recovery systems, with the goal of keeping consumption below 4 m³ per ton of paper produced. A concrete commitment that allows us to combine production efficiency and sustainability, ensuring responsible water resource management, in line with European standards and a long-term vision focused on environmental protection.

READ THE INTERVIEW

TRANSLATION

“INDUSTRIA DELLA CARTA” – “Paper Industry”

Special Feature on Water Treatment

Sustainable Water Management

From Water to a Global Commitment

By Raffaella Quadri

The paper industry is investing in advanced technologies to optimize water consumption and treatment, reducing its environmental impact. Among the solutions adopted are eco-friendly treatments for incoming water and the recovery of wastewater, using systems that minimize waste and promote the reuse of water resources. Thanks to these innovations, a major Italian paper mill reduced its water withdrawal by 9% in 2023 and aims for increasingly efficient water use, aligning with the ambitious European sustainability targets.

Paper producers have always been committed to circular economy principles and environmental protection. Paper itself is an inherently circular material, as it originates from natural raw materials that can—and must—be recovered and recycled.

However, integrating these principles into corporate policies requires commitment and consistency.

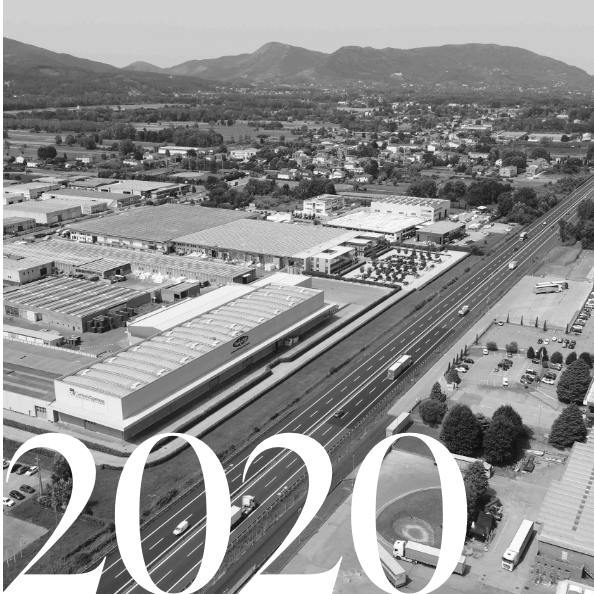

Cartiere Carrara, one of Europe’s leading integrated tissue paper producers, operates in 50 countries worldwide and boasts a history spanning over 150 years. The company has made environmental stewardship and resource conservation the foundation of its business approach, including a responsible approach to water consumption.

Technology for Water Treatment

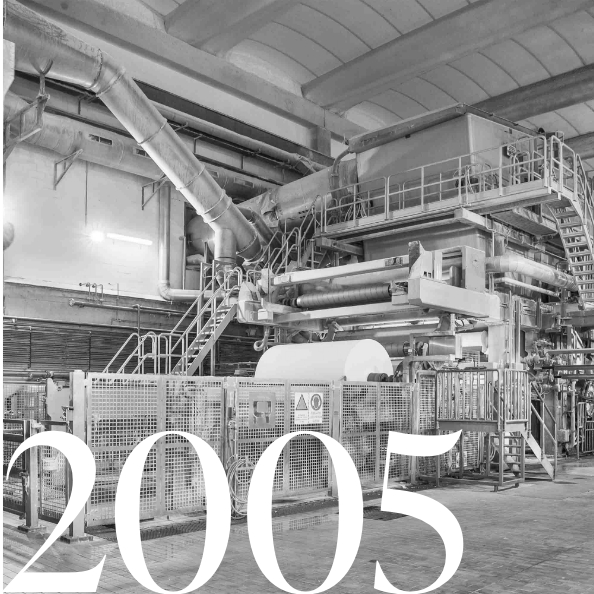

“Water is a fundamental resource for the paper industry. This is why paper mills have historically been located near rivers or in areas where surface aquifers are abundant,” explains Mario Carrara, Vice President & Chief Growth Officer of Cartiere Carrara. When asked about how water resources are managed in their facilities, he continues:

“Water is essential for binding and homogenizing cellulose fibers. It also acts as a solvent, transporting fibers throughout the production chain. Given its importance and extensive use, our main goal is twofold: reducing water consumption and optimizing its use in production processes. To achieve this, we are adopting advanced technologies for water treatment, both at the intake and discharge stages.”

However, these efforts come with challenges. “Water management issues extend beyond production needs,” Carrara adds. “Climate change is significantly affecting the availability and quality of water resources, making long-term planning and the adoption of resilient solutions essential.”

Investing in Water Consumption Reduction

The paper industry’s focus on efficient water use has driven significant improvements. “Over the years, our sector has significantly reduced water consumption thanks to a combination of technological advancements, regulatory developments, and improved management practices,” explains Carrara.

Closed-loop systems, process enhancements, and advanced wastewater treatment technologies have optimized water use, while increasingly stringent European regulations and environmental certifications have further promoted responsible management, minimizing waste.

Cartiere Carrara has been at the forefront of these efforts, constantly improving its water footprint. In 2023, the company reduced water withdrawal by 9%, totaling 1,374,908 cubic meters compared to the previous year. “This figure includes both surface water—over 710,000 cubic meters—and groundwater extraction, around 664,000 cubic meters,” Carrara details.

These achievements, as documented in the company’s Sustainability Report, were made possible through continuous research and development. “Through targeted investments and ongoing technological advancements, we have progressively reduced specific water consumption per ton of paper produced, reaffirming our commitment to a sustainable approach,” says Carrara. “This not only minimizes our environmental impact but also allows us to recover and reuse an increasing volume of water within the production cycle—an area we aim to improve even further in the coming years.”

Optimizing Water Use: From Intake to Discharge

Investments in water resource optimization drive Cartiere Carrara to explore and implement new, cutting-edge solutions across its production sites.

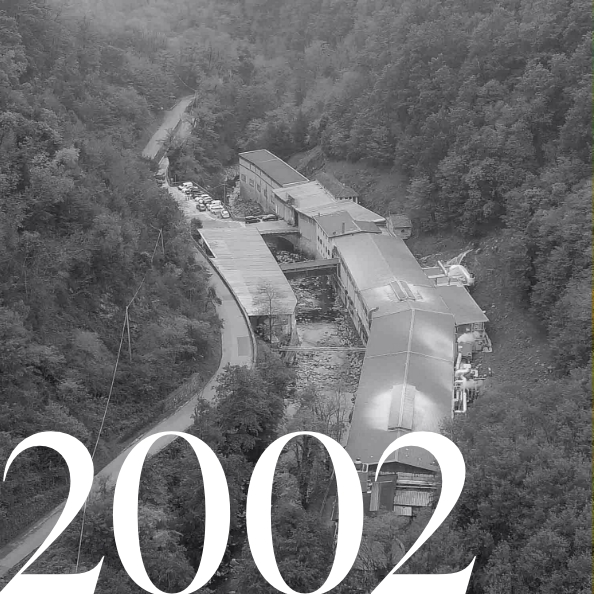

A key example is the Pratovecchio facility in the Arezzo province, where water from the Arno River requires specialized treatment. “The intake water undergoes carefully designed eco-friendly processes,” explains Carrara. These treatments occur in two phases: mechanical and biochemical.

- Mechanical phase: Progressive filtration removes coarse organic and inorganic suspended particles.

- Biochemical phase: An ozone treatment eliminates up to 95% of organic matter, followed by UVC light sterilization, making the water microbiologically pure and more efficient for industrial use.

“This technology has a tangible impact on sustainability,” Carrara emphasizes. “The bactericidal effect of ozone and ultraviolet rays does not produce toxic by-products, reducing risks for both workers—ensuring better occupational health and safety—and the environment.”

Beyond intake water treatment, Pratovecchio has also improved wastewater management. In 2023, a new purification plant was introduced, allowing 10% of treated water to be reintroduced into the production cycle. “Our goal is to increase this percentage, using eco-friendly systems to reprocess and reuse even more water,” states Carrara.

Tailored Solutions for Water Management

Implementing these solutions comes with challenges, as modifying water management processes in an industrial setting often requires overcoming technical and financial barriers. However, with over 150 years of experience, Cartiere Carrara has found ways to tackle these challenges successfully.

“Thanks to our long history and continuous innovation, we have integrated sustainable solutions without compromising production quality,” explains Carrara. For instance, in Pratovecchio, adopting advanced treatment systems has enhanced water efficiency and reduced environmental risks, overcoming technical and logistical challenges along the way.

“Each new system takes time to integrate into operations, but the expertise we’ve developed allows us to navigate these challenges effectively,” he adds.

Commitment to the UN Global Compact

In 2023, Cartiere Carrara published its Sustainability Manifesto, setting ambitious targets, including responsible water consumption as one of the company’s key priorities. Specifically, the company aims to keep its average water consumption below 4 m³ per ton of paper produced, in alignment with European sustainability goals.

A major milestone in this journey was joining the UN Global Compact in 2023. “This step further strengthens our commitment to the ten fundamental principles and the 17 Sustainable Development Goals (SDGs),” Carrara explains. Among these, SDG 6—Ensuring clean water and sustainable water management for all—is central to our mission.

By joining the UN Global Compact network, Cartiere Carrara aligns with universal principles on human rights, labor conditions, environmental protection, and anti-corruption efforts, committing to annual progress reporting, ensuring both transparency and accountability.

However, this is just the beginning. “In 2025, we will continue our efforts in innovation and experimentation to meet these targets, extending successful solutions to other facilities, further reducing our environmental footprint,” concludes Carrara.

What is the UN Global Compact?

The UN Global Compact is the world’s largest corporate sustainability initiative, promoting human rights, environmental protection, fair labor conditions, and anti-corruption efforts. Launched in 2000 following an appeal by then UN Secretary-General Kofi Annan, it encourages businesses to align their strategies with global sustainability objectives.

With over 20,000 companies from 167 countries, the initiative fosters a global network committed to integrating sustainability into corporate strategies and operations.

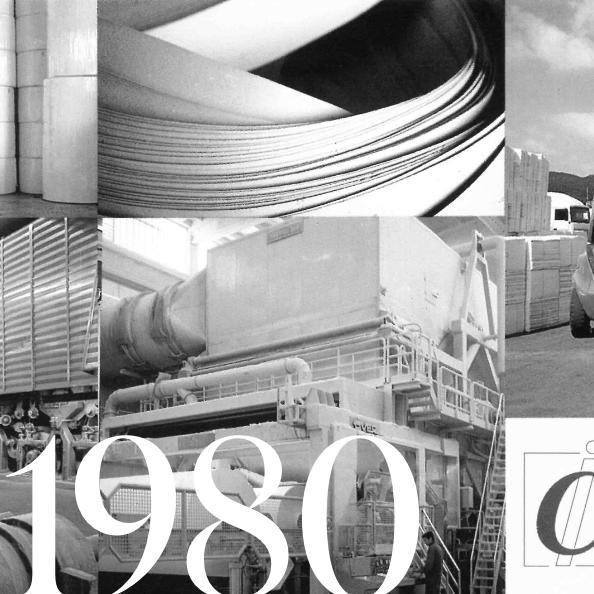

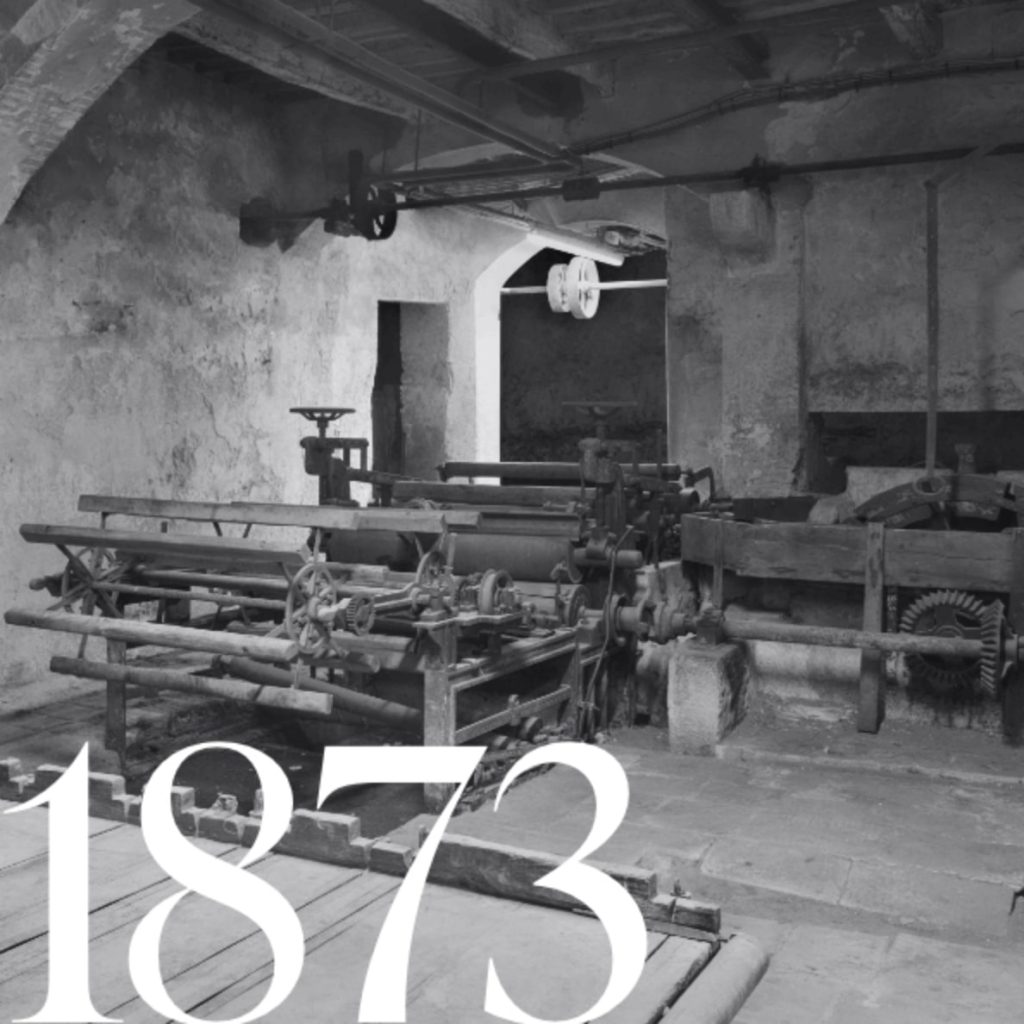

150 Years of Tissue Paper Innovation

Since 1873, Cartiere Carrara has been a family-driven business, blending tradition and innovation. With seven production sites, ten continuous paper machines, and an annual capacity of 300,000 tons, the company is a leader in Italy and Europe, exporting to over 50 countries and employing 850 people.

With a portfolio covering household, professional, and private-label products, Cartiere Carrara continuously invests in R&D, ensuring high-quality standards. Sustainability is central to its operations, with initiatives in circular economy, energy efficiency, and responsible resource management.

From energy self-production to reforestation projects like Kilometroverde Lucca, Cartiere Carrara is committed to environmental stewardship and sustainable growth.